Beijing: 1# Chaoqian Road, Science Park, Changping District, Beijing, China

Shanxi: 5-1#, Zone 2, 69 JinXiu Avenue, YangQu, Taiyuan, Shanxi, China

North Region: +86-10-18515571376

South Region: +86-10-18515571396

Applications of CO2 Laser in the Food and Beverage Industry

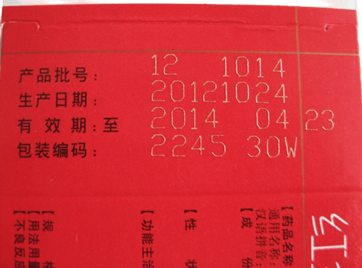

CO2 lasers have found innovative applications within the food industry. From branding meat products to marking eggshells and freshly baked bread, CO2 lasers serve a wide array of purposes. They are also extensively utilized in packaging and bottling, enabling rapid marking of information such as production dates, batch codes, barcodes, and QR codes on materials.

Laser marking offers the advantages of permanence and tamper-resistance, making it suitable for a variety of packaging materials. This technology eliminates the use of inks and solvents on production lines, resulting in a cleaner, more efficient, and environmentally friendly process. Laser marking is particularly prevalent in sectors such as breweries, dairy, grains, and soft beverages.

1. PET Marking:

Plastic bottles are widely used in the beverage industry, typically made from PET, a transparent, sturdy, lightweight, and safe plastic. PET exhibits excellent absorption at a wavelength of 9.3 μm, resulting in enhanced contrast and greater visibility for markings. This technology can be utilized for high-speed dynamic marking on production lines. Laser marking is both permanent and tamper-proof.

2. Food Marking:

CO2 lasers can directly mark a variety of food items, including meats, cheeses, fruits, vegetables, and baked goods. Laser marking allows for the rapid application of product information, such as production dates, batch codes, and origin details, directly onto the food. Additionally, logos, graphics, and slogans can also be marked, enhancing brand visibility and consumer engagement.

3. Perforating Freshness Packaging:

Laser perforation of freshness packaging can extend the shelf life of certain fruits and vegetables compared to non-perforated packaging, thereby preserving product freshness. CO2 lasers are utilized to create precise perforations in plastic packaging films according to specific requirements. The spacing of the perforations can be adjusted flexibly based on the type of product.

4. High-Speed Marking of Beverage Packaging:

CO2 laser marking is a highly effective solution for the beverage industry, offering superior quality and rapid production speeds. The operational speed of high-quality CO2 laser marking can reach up to 70,000 bottles per hour (20 bottles per second). Beverage marking systems must be capable of functioning in harsh environments and withstand routine cleaning to comply with stringent hygiene regulations.

5. Packaging Marking:

CO2 lasers can leave high-quality and clear permanent markings on packaging materials such as paper and cardboard. The contrast depends on the background color of the material, but it is generally excellent. Information such as expiration dates, batch codes, barcodes, and QR codes can be dynamically applied on the production line and continuously updated as needed.